Get a German R3 should fit better.Radius gauges arrived. To the best of my measuring abilities, the neck of my MIM Fender Player HSS Floyd Rose does seem to be 12" radius.

I'll probably keep it the way it is and live with slightly higher high and low E string nut slots.

The 43 mm bolt through Gotoh is your best bet. The Japan Ibanez Edge actually is made by Gotoh and has the 1996 nut.This is a really interesting thread as I have a Gotoh 1996T on one of my Shur's and they are really gear. I have a Korean Ibanez rg350/70 which I would like to bring back from the dead - the trem system is knackered so was thinking of replacing with a Gotoh but I don't know what the nut size r3/r2 etc but I don't think the Gotoh would be compatible as the Ibanez is a thru neck bolt one I might just change the clamps though as there was a rough one which would sometimes break the string.

Sorry to hijack the thread

Buy another neck cut for a floyd nut.Here's another one for @Andy Eagle or anyone else with experience.

How feasible is it to convert a regular trem Stratocaster to Floyd Rose? Obviously major routing on the body, but can a regular Stratocaster neck be converted to have space for a locking nut? You could chip away the extra wood in front of the regular nut and even out the area to make space for the locking nut, but it seems that there is not enough length there left, and I wouldn't want the locking nut to "overhang".

View attachment 100489

An overhang is quite normal on a strat neck and no problem at all . Fitting a Floyd nut is a job for a tech though. Only necks designed to be used with a Floyd have a full shelf.Here's another one for @Andy Eagle or anyone else with experience.

How feasible is it to convert a regular trem Stratocaster to Floyd Rose? Obviously major routing on the body, but can a regular Stratocaster neck be converted to have space for a locking nut? You could chip away the extra wood in front of the regular nut and even out the area to make space for the locking nut, but it seems that there is not enough length there left, and I wouldn't want the locking nut to "overhang".

View attachment 100489

Certainly an option but not needed.Buy another neck cut for a floyd nut.

File a grove in the underside of the locknut so you can get the key in. You can buy some sizes with that done but it's not that hard to mod one.I’ve put a Floyd on a stock strat and the nut does overhang slightly, but is quite secure.

The worst part is I have to take the nut off to adjust the truss rod.

Unless you’re particularly attached to the neck or it’s a budget job, getting a neck with a shelf pre-done, or at least a heel-adjust truss rod would be ideal.

And kind of mostly wrong.Kinda late to the party but here we go!

First off, the possible quick fix, check to see if the Floyd saddles are in the correct radius.

I've seen guitars straight from the shop with misconfigured saddles resulting in an awkward radius.

Definitely a possibility of error from the manufacturer/ QC tech / etc.

Floyd top lock nuts aren't recommended for filing, if you do and go too deep, your strings won't lock from the locking pads.

To adjust the correct string height, you can do what @Romo82 has said with shims to balance the height/radius correctly.

The other alternative is to file down the nut shelf with a flat file/ sanding block, being very critical you don't sand too deep,

or sand unevenly which will result in more problems.

Floyd conversions to strats could potentially work with a routed non-fine tuner Floyd with locking tuners.

This configuration is very similar to Guthrie's Charvel signature model. The problem with adding a Floyd nut is the lack

of space for it on top. Don't get me wrong, people have done it in the past, and still do. But problems can occur from

tuning instability, and altering the scale length, resulting in bad intonation. It's "possible" but a skilled luthier with the

proper tools would need to do the job, but even then I always thought it looked weird with those conversions.

The alternative drop in trem for strats that I've seen many players use would be the Vega Trems. Pricey, but they look

like a lot of fun! Allows you to do full dive bombs, pull ups without the need of any drilling or hard work. Tuning stability

would vary depending if you have locking tuners, greased up string tree's/nut etc.

Hope that helps!

Make sure the lock clamp is positioned correctly. The bottom is curved in one direction and straight on the perpendicular side.Getting a little frustrated with this MIM Stratocaster and FR Special. Played my first show last night with it and at one point the low E went to Eb without much wiggle action, maybe just a little chordal vibrato was all I did.

It's possible I didn't lock down hard enough, but this is not my first FR rodeo. I have/had many FR equipped guitars. Some Original FR (a Carvin, a Jackson, a Dean), mostly Korean ones. I have two good ones right now, ESP SN1000-FR and Schecter Exotic. Never had such a hard time to keep tuning stability in a FR.

I think the low E and A string might be slipping at the nut. There are some markings at the underside of the clamp where the strings run. Maybe I need to roughen up the underside a little with sandpaper to get rid of the chrome? Bad idea?

View attachment 101157

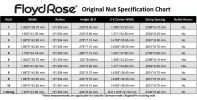

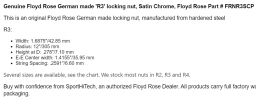

I know @Andy Eagle recommends to buy a German made locking nut. However their R3 are 10" radius, and my neck is 12" (both by spec and my own measurement too). Anyone know a high quality R3 for 12" radius?

this may answer some of your questions.My first questions are related to the locking nut.

I started doing a setup on the MIM Fender Player above. 0.095 string set. Straightened the neck a bit to get to 0.006 relief for the low E. String height at 12th fret was 5 and 4 64ths (low/high E) after that, which works for me for now.

Now, the nut. Low E is 0.030, High E is 0.025 at first fret. I'd like to get to 0.018. Good thing though that I measured all strings, because the D and G are at 0.018 already, so I can't uniformly make the nut thinner at the bottom.

Fender says the neck radius should be 12", and an R3 nut should also be 12". From the measurements something is off, seems like the nut is too flat or the neck is too rounded (I doubt that).

Q1: Is it really an absolute no-no to file down the individual slots on a locking nut?

Q2: Is it possible that the locking nut of this "Floyd Rose Special" setup is out of spec, and buying another (official) R3 locking nut might actually have the correct 12" radius and solve my problem?

R3 is 12" radius but I believe it is taller than the special nutView attachment 101158

Old R3 is 10".I looked at my ESP locking nut "clamps". I noticed that it has a slight groove on the underside, orthogonal to the strings. What that does is reduce the surface area where it presses on the strings (just at the beginning and end, instead of the whole extent of the clamp). Maybe I'll try making such a groove in my Special nut before replacing the whole nut.

I found an eBay seller claiming they have the German made nut, and despite sporting the above picture (saying R3 are 10") they also spec their R3 as 12".

https://www.ebay.com/itm/302017905330

View attachment 101162