LAYGO

Experienced

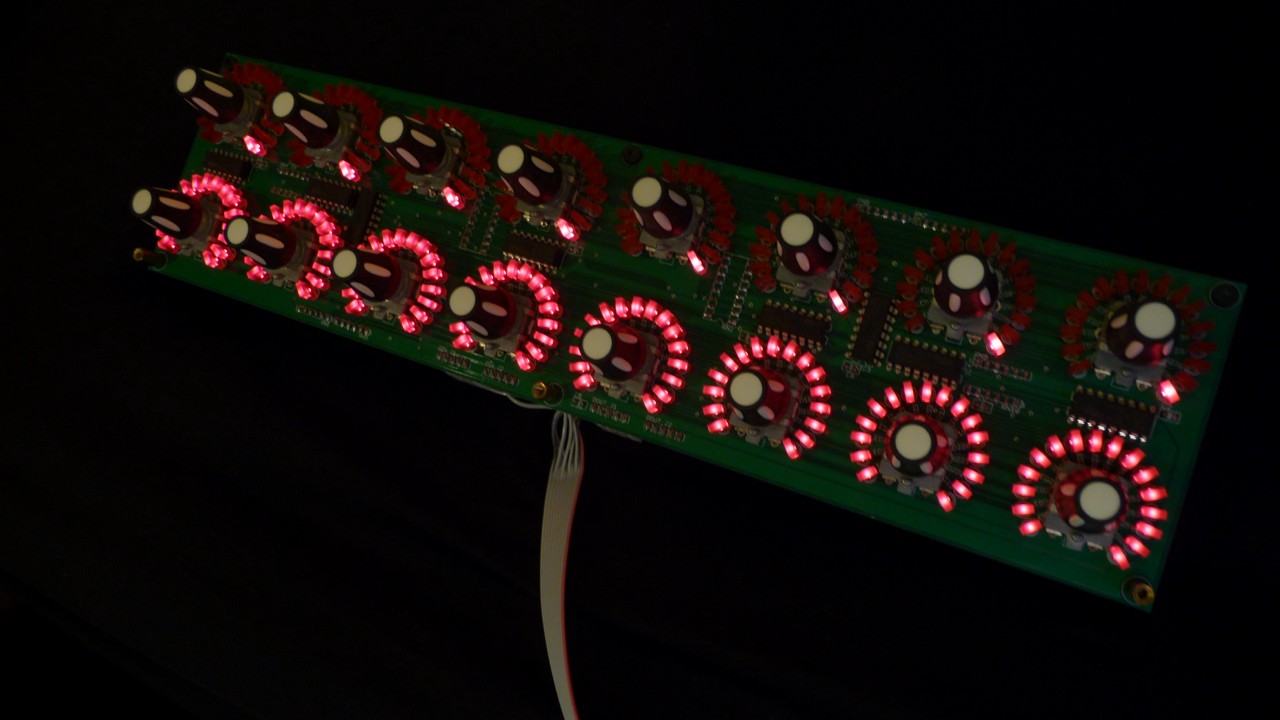

I've been dreaming about a 1U (maybe 2U?) rack with just knobs & LED rings. I've worked with another member here who I paid for parts, etc to get some decent progress, but I think a lot of the motivation was lost with the introduction of the RAC12 + life. (I am by no means disparaging this other member). That project was all the way back in 2011-2012!

Well, I stumbled upon these videos earlier today & it got me all pumped again because it's like a perfect vision of what I wanted to get implemented. I believe an LCD screen is not necessary when the LED ring will give you an idea of what the value is. Do you really care if it's 4.76 vs 6.28? No, rotate until it sounds good to your ear. An LCD might be useful to give you an idea of what the knob you're rotating is for though.

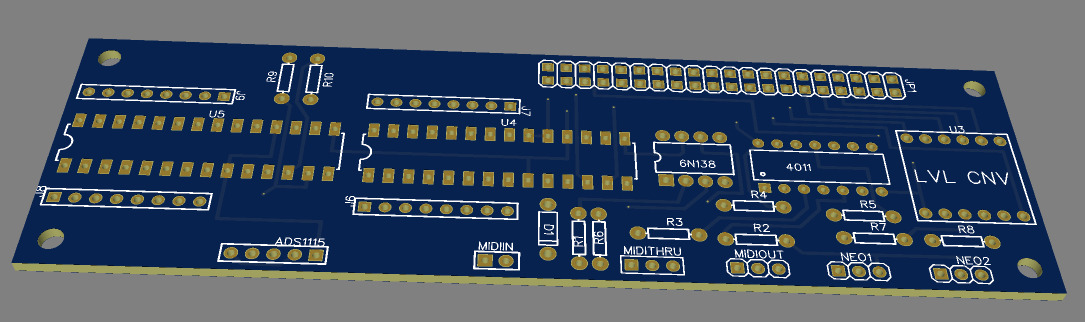

Here is the discussion on group buys for the boards:

https://muffwiggler.com/forum/viewtopic.php?t=217920

http://midibox.org/forums/topic/21095-lre-4x1-breakable-rgb-led-ringrotary-encoder-pcb-bulk-order

Well, I stumbled upon these videos earlier today & it got me all pumped again because it's like a perfect vision of what I wanted to get implemented. I believe an LCD screen is not necessary when the LED ring will give you an idea of what the value is. Do you really care if it's 4.76 vs 6.28? No, rotate until it sounds good to your ear. An LCD might be useful to give you an idea of what the knob you're rotating is for though.

Here is the discussion on group buys for the boards:

https://muffwiggler.com/forum/viewtopic.php?t=217920

http://midibox.org/forums/topic/21095-lre-4x1-breakable-rgb-led-ringrotary-encoder-pcb-bulk-order

Last edited: