Piing

Axe-Master

I've found the Service Manual of the Roland VG-8. That was a real Service Manual! like the old time TVs

It starts with the part numbers of all the mechanical components, including an exploded view

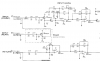

A block diagram of the circuit with a description of the functions of each block

Exhaustive parts list of all the components, from washers and screws to IC references

Step by step "Test Mode" diagnose. It can actually tell you which IC is faulty

Troubleshooting logic tree

PCB assembly and wiring diagrams

Internal wiring diagrams

It is interesting to watch

(you may need to install this Adobe Acrobat Reader extension if you do not have Asian fonts. It is bilingual)

It starts with the part numbers of all the mechanical components, including an exploded view

A block diagram of the circuit with a description of the functions of each block

Exhaustive parts list of all the components, from washers and screws to IC references

Step by step "Test Mode" diagnose. It can actually tell you which IC is faulty

Troubleshooting logic tree

PCB assembly and wiring diagrams

Internal wiring diagrams

It is interesting to watch

(you may need to install this Adobe Acrobat Reader extension if you do not have Asian fonts. It is bilingual)

Attachments

Last edited: