For me, I have them set on delay and reverb wet/dry control so I vary that by scene. I usually create a preset per song, so having the bridge wetter than the chorus is useful.Why not just change parameters on different block channels?

Why would using scene controllers be a better choice?

How are you using them?

Control Switch is a good choice... But you can also do it with a Scene Controller on scene changes.yeah - I really want to tweak my leslie effect to have a ramping from low to high speed just like a real one would do. Gotta dig back into it after the holidays!

I have a Rotary block that does that based on switching between channels A-C, A=slow, B=fast and C=brake. Setting the Hold function to increment the channels makes it possible to ramp up or down or hit the full stop quite easily. I’m happy with how it turned out.I really want to tweak my leslie effect to have a ramping from low to high speed just like a real one would do.

Same, except I didn't include a brake channel, not sure I need it, and having it in the channel sequence is a bit awkward.I have a Rotary block that does that based on switching between channels A-C, A=slow, B=fast and C=brake. Setting the Hold function to increment the channels makes it possible to ramp up or down or hit the full stop quite easily. I’m happy with how it turned out.

It’d be easy to use separate scenes to switch the channels, but I didn’t want to waste additional scenes just to change an effect, especially one that we tend to use dynamically. Instead I assigned the tap action to bypass/enable the rotary and the hold function of the same switch handles the channels.

I’ll try to update this tomorrow with the block from my library.

The brake is used by keyboardists often, just as the other two speeds are. I use it the same way, as a counterpoint to the fast setting.Same, except I didn't include a brake channel, not sure I need it, and having it in the channel sequence is a bit awkward.

Do you really like it Greg? It's not one of the classic Leslie sounds in my head.

Not if you’re trying to match the authentic speeds.Tap tempo is very good for controlling Leslie (Rotary).

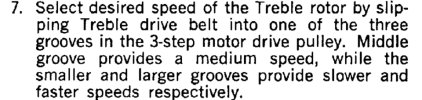

The research I've done says 48 rpm and 408 rpm for the top rotor, and about 5/6 (0.8333, yielding 40 and 340 rpm) of those for the low rotor are the usual speeds, given drive belts in good shape. They mention a 'middle pulley' in a few sources, which implies there are a couple other pulley choices available in the unit, which I assume give different speeds, since it would be a waste of pulleys to have extras that don't make any difference....Not if you’re trying to match the authentic speeds.

I use the values from Wikipedia’s article. According to the manual there’s a three-step pulley to adjust the rotor speeds in addition to the two speeds of the motors, so the reported RPM values could vary depending on which pulley step is used.The research I've done says 48 rpm and 408 rpm for the top rotor, and about 5/6 (0.8333, yielding 40 and 340 rpm) of those for the low rotor are the usual speeds, given drive belts in good shape. They mention a 'middle pulley' in a few sources, which implies there are a couple other pulley choices available in the unit, which I assume give different speeds, since it would be a waste of pulleys to have extras that don't make any difference....

Would love to spend a day with a real one and do some measurements....

Good find on the manual. Will have to sit down with it on the computer and do the RTFM thing.I use the values from Wikipedia’s article. According to the manual there’s a three-step pulley to adjust the rotor speeds in addition to the two speeds of the motors, so the reported RPM values could vary depending on which pulley step is used.

View attachment 112514