Piing

Axe-Master

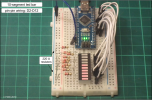

This is the prototype of a PM2.5 monitor built with Arduino. I have used a Dremel with a Cut-Off Wheel and then a small file.

Any tip to make it look better?

I've found these cheap tin boxes with a transparent window and I intend to build more of these PM2.5 meters as gifts. I never knew what to bring when invited to a birthday, but now I got the idea of this DIY gift

Any tip to make it look better?

I've found these cheap tin boxes with a transparent window and I intend to build more of these PM2.5 meters as gifts. I never knew what to bring when invited to a birthday, but now I got the idea of this DIY gift